Many brands today want packaging that looks good, lasts long, and is friendly to the environment. This is why hessian jute bags, also called burlap bags in North America, are becoming very popular. They are strong, reusable, biodegradable, and give a natural, eco-friendly look that customers like.

However, buying in bulk is not as simple as picking a product from a catalog. Important details such as fabric weight, lamination, printing options, and supplier quality can make a big difference, especially when you’re ordering thousands of units or importing across borders.

This guide helps buyers make smart, cost-effective decisions when sourcing hessian jute bags in large quantities.

Common Categories of Hessian Jute Bags in Bulk Supply

Wholesale jute suppliers generally organize their offerings into the following commercial formats:

| Category | Typical Use Case | Standard Features |

| Agricultural Sacks | Grain, potatoes, cocoa, charcoal | Coarse weave, 12–14 oz, drawstring or open-mouth |

| Retail Totes | Grocery stores, boutiques, farmer’s markets | Laminated lining, flat or gusseted, cotton handles |

| Drawstring Pouches | Cosmetics, jewelry, gifts, party favors | Fine weave, unlaminated, custom print ready |

| Wine Bags | Event gifts, F&B packaging, corporate kits | Bottle-sized, stitched partitions, rope handles |

| Promotional Bags | CSR giveaways, trade shows | Custom print, color-dyed jute, reinforced seams |

Each type of jute product varies in raw material quality, finishing, handle design, and lamination all of which affect price, shipping volume, and durability.

How to Choose a Wholesale Jute Bag Supplier

Selecting the right wholesale supplier is arguably the most critical stage in your bulk buying journey. Poor supplier selection can lead to delayed shipments, inconsistent quality, failed regulatory inspections, and brand reputation damage. On the other hand, a reliable, well-audited supplier can become a strategic long-term partner, helping you scale with confidence, reduce defect rates, and negotiate better terms over time.

The following supplier vetting framework is designed for serious buyers who value operational continuity, compliance, and scalable quality.

Factory vs Trading Company vs Agent: Know the Sourcing Model

Understanding your supplier’s business model determines how much control you’ll have over customization, quality assurance, and pricing transparency.

| Supplier Type | Pros | Cons |

| Factory (Direct Manufacturer) | Lower cost, faster custom work, QC visibility | May lack English fluency, limited export compliance |

| Trading Company | Wider SKU variety, better communication, low MOQ | Higher cost per unit, less control over factory |

| Sourcing Agent | Negotiates for you, QC oversight, local representation | Added fees, varies by experience & reliability |

Whenever possible, request factory photos, business registration, and audit certificates to verify the actual production site.

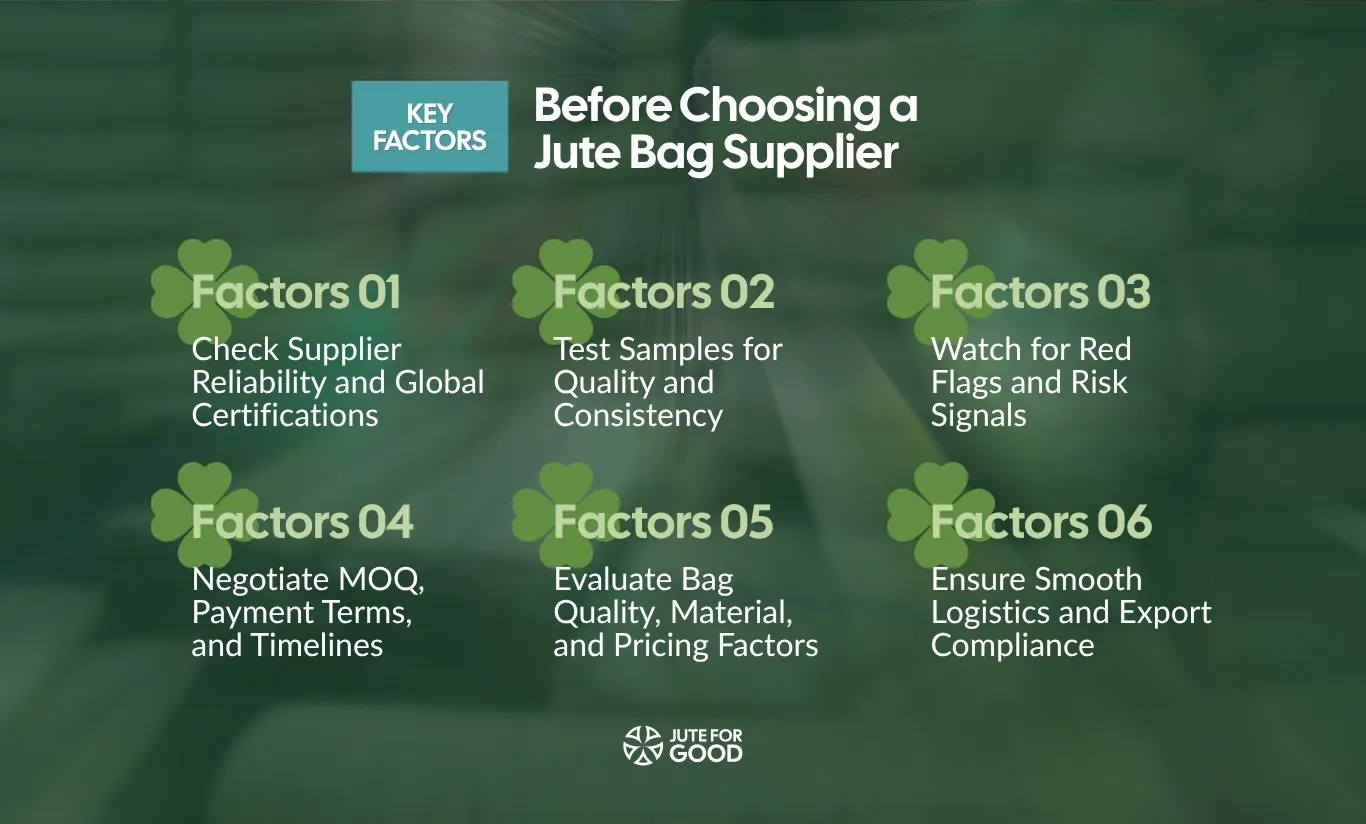

Factors to Consider Before Choosing a Jute Bag Supplier

Before finalizing a jute bag supplier, it’s important to look beyond price. Reliability, product consistency, ethical practices, and logistical efficiency can make or break a long-term sourcing partnership. The best suppliers not only deliver quality bags but also follow international standards, maintain transparency, and provide strong after-sales communication. Below are the key factors you should evaluate before making your decision.

Reliability and Certifications

A dependable jute bag manufacturer should hold valid certifications that prove both product quality and ethical labor standards. These certifications ensure that the factory follows safe production methods, maintains consistent quality, and meets environmental guidelines.

Examples include:

- ISO 9001 for quality management systems

- OEKO-TEX Standard 100 for textile safety

- GOTS for certified organic jute production

- Fair Trade or SA8000 for ethical and fair labor practices

- Sedex or BSCI for audited and transparent working conditions

Always ask for valid certificates and confirm they’re issued by internationally recognized organizations such as SGS, TÜV, or Control Union.

Sample Testing and Quality Assurance

Never place a bulk order without physically testing samples first. Sample testing helps you verify product strength, stitching quality, and print accuracy before mass production begins.

Best practices include:

- Request 2–3 sample units per SKU with full customization (print, color, handles).

- Test load capacity by filling each bag with 10–15 kg and hanging it for 24 hours.

- Check stitching, seams, and color consistency.

- Wash and dry one bag to see if it shrinks or fades.

- Send a sample to a lab if you need tensile or toxicity testing for export compliance.

If a supplier avoids sending samples or insists on full payment before sampling, take it as a warning sign.

Red Flags and Risk Signals

Good suppliers communicate clearly, share details willingly, and stick to agreed specifications. Poor communication often signals deeper operational issues. Be cautious of vendors who:

- Take too long to respond or avoid technical questions.

- Change specifications or minimum order quantities mid-discussion.

- Refuse to share certifications, past client references, or factory photos.

- Give inconsistent pricing or hide setup fees.

Trustworthy suppliers are transparent about costs, timelines, and factory operations.

Negotiating MOQ, Payment Terms, and Lead Time

Serious suppliers are flexible when they see long-term potential. You can often negotiate better pricing or lower minimum order quantities by committing to repeat orders or standard packaging options. Discuss:

- Minimum order quantity (MOQ) adjustments.

- Payment structure, such as 30% deposit and 70% after inspection.

- Delivery schedules that fit your logistics plan.

Clear communication on these points prevents delays and cost disputes later.

Quality and Pricing Factors

The quality and cost of jute bags depend on several technical details, including fabric weight, weave density, lamination, handle strength, and stitching. Understanding these helps you pick the right balance between price and performance.

Fabric Weight (GSM) and Weave Density

Fabric weight, measured in GSM (grams per square meter), determines the bag’s durability, printability, and texture.

- 140–180 GSM: Light, for decorative or drawstring pouches.

- 180–250 GSM: Medium, for promotional and retail bags.

- 300–340 GSM: Heavy, ideal for grocery or branded bags.

- 370+ GSM: Industrial grade for exports and heavy goods.

Tightly woven fabric ensures consistent quality and prevents fraying during transport.

Lamination, Lining, and Water Resistance

Lamination adds a plastic layer (usually PP or LDPE) that improves water resistance and print clarity.

- Laminated bags are best for humid climates and premium packaging.

- Unlaminated bags are cheaper, biodegradable, and suitable for dry goods.

Some buyers add cotton or non-woven linings for extra structure and a premium feel.

Handle Types and Load Capacity

Handles affect both appearance and strength:

- Cotton rope handles for gifting.

- Flat cotton handles for heavy groceries.

- Jute self-handles for low-cost bulk use.

- Reinforced handles for loads above 10 kg.

Stitching and Finishing

Look for double stitching on the base and gusset, overlock seams for light bags, and piping for premium finishes. Food packaging may need hemmed edges to prevent fiber shedding.

Dimensional Accuracy and Compliance

Inconsistent bag sizes can cause issues in automated packing and shipping. Set clear tolerances (±1 cm) and check base depth and folding dimensions. For export markets, ask for tests on tensile strength, color fastness, and chemical safety (REACH, ISO).

Bulk Pricing

The true cost of jute bags includes materials, labor, printing, freight, and customs. Buyers should compare suppliers not just by unit price but by total landed cost.

Global Price Range (per unit, 1,000 pcs)

- India: $0.35–$0.75

- Bangladesh: $0.40–$0.80

- China: $0.60–$1.10

- Vietnam: $0.65–$1.25

- Turkey: $0.85–$1.50

Prices rise with lamination, custom printing, or smaller order volumes.

Logistics, Export Protocols, and Customs Compliance

Bulk sourcing usually involves international shipping, so understanding export documentation and Incoterms is essential.

Common Incoterms

- FOB: You manage freight and insurance.

- CIF: Supplier handles shipping and insurance.

- DDP: Supplier covers full delivery and customs.

For beginners, CIF or DDP are simpler options.

Essential Export Documents

- Commercial invoice with HS code and unit value.

- Packing list with size and weight details.

- Bill of Lading, Certificate of Origin, and Fumigation Certificate.

- Inspection report (if third-party QC was used).

Packaging and Freight Optimization

Use bale or carton packing to save container space. A 20ft container holds about 80,000 folded bags, while a 40ft HC can carry up to 180,000, depending on GSM and lamination.

To minimize risks, work with an experienced freight forwarder, insure your shipment, and verify customs classification (HS code 6305.10.00).

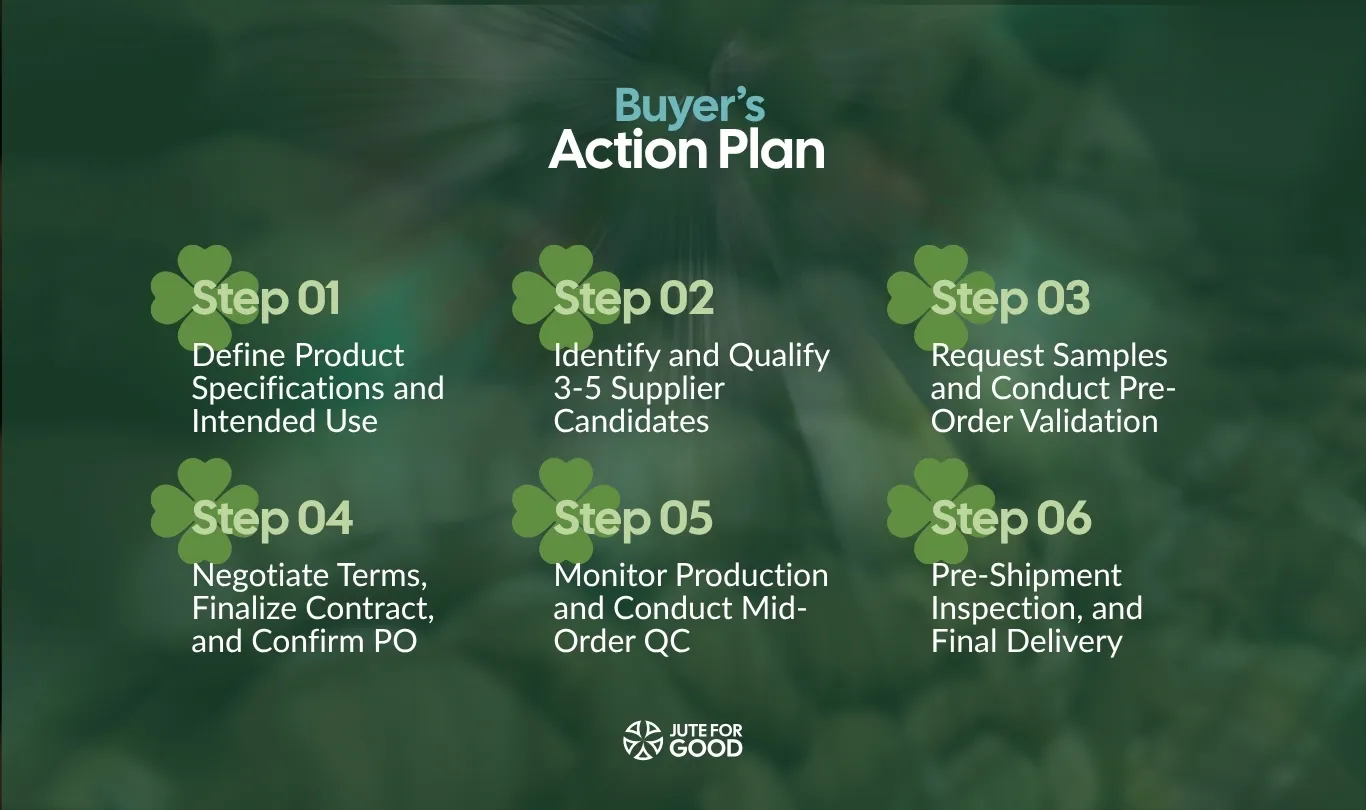

Buyer’s Action Plan for Buying Jute Products

Bulk procurement of hessian jute bags is not a one-click transaction. Successful buyers, especially those dealing with multi-thousand-unit orders, custom branding, or international delivery treat the purchase as a structured project. Below is a proven, six-phase action plan to move from specification to delivery with quality assurance and margin protection built in.

Step 1: Define Product Specifications and Intended Use

Start with absolute clarity on what you need and why. This forms the foundation of your RFQ (Request for Quote) and reduces supplier misinterpretation.

- Determine size, GSM, weave density, and lamination needs

- Select handle type and customization requirements

- Match bag style to target application (retail, agriculture, gifting, etc.)

- Decide on compliance standards (e.g., OEKO-TEX, REACH)

Include a tech pack or spec sheet PDF in your initial outreach to suppliers.

Step 2: Identify and Qualify 3-5 Supplier Candidates

Sourcing from Alibaba, trade shows, or third-party sourcing platforms? Qualify your shortlist before requesting samples.

- Confirm certifications and export registration

- Request client references and factory photos

- Evaluate response speed, technical clarity, and willingness to negotiate

Use the 10-point supplier evaluation scorecard from Section 5 to assess each vendor objectively.

Step 3: Request Samples and Conduct Pre-Order Validation

Never skip this stage even if it costs extra. Sample testing prevents catastrophic order errors and establishes quality benchmarks.

- Order 2–3 units of each SKU with full specs

- Perform drop/load/wash testing as per use case

- Measure dimensions, print alignment, handle reinforcement

- Assess packaging and labeling formats

- Solicit buyer or stakeholder feedback internally

If samples fail to meet specs, clarify gaps in writing before moving forward.

Step 4: Negotiate Terms, Finalize Contract, and Confirm PO

At this stage, move beyond casual email exchanges to formal documentation.

- Negotiate price tiers based on volume and delivery terms

- Define payment structure (e.g., 30/70 with escrow or LC)

- Specify Incoterm (FOB, CIF, DDP) and shipping timeline

- List all product specs, packaging format, and QA clauses in PO

- Include penalties for late delivery or non-compliance

Use a bilingual PO with clear dispute jurisdiction and governing law.

Step 5: Monitor Production and Conduct Mid-Order QC

Bulk jute bag production (especially for laminated, printed, or customized orders) typically spans 15–45 days.

- Schedule check-in calls or WeChat updates with your supplier

- Request photo/video evidence of raw materials and print runs

- Hire a third-party QC firm (e.g., QIMA, Intertek, SGS) to inspect production at 50–70% completion

- Use a mid-order inspection report to authorize or delay balance payment

QC at this stage is far less expensive than post-shipment remediation.

Step 6: Pre-Shipment Inspection, Customs Clearance, and Final Delivery

Before containers are sealed or cargo is palletized:

- Verify final inspection report with photo documentation

- Cross-check final packaging and labeling against customs requirements

- Ensure all export docs (invoice, CO, B/L, fumigation cert) are issued and shared digitally

- Book ocean freight, confirm ETD (Estimated Time of Departure)

- Coordinate customs clearance and last-mile delivery in your country

If duties or inspection fees were pre-paid by your supplier (DDP), validate invoice evidence to avoid double-charging.

Common Mistakes to Avoid in Bulk Jute Purchasing

Many bulk buyers make similar mistakes when sourcing jute bags, especially when they rush the process or depend too much on trust. Below are the most common problems and how to prevent them.

1. Not Checking Fabric Weight and Finish

A common mistake is accepting product descriptions without confirming the actual GSM or lamination. Terms like “premium” or “heavy-duty” can be misleading if not backed by testing. As a result, bags may tear easily, look rough, or fail moisture resistance. The solution is to always request labeled samples and verify the GSM through physical testing before placing your order.

2. Misunderstanding Shipping and Incoterms

Many buyers believe that CIF covers everything, including customs and local delivery. In reality, unclear shipping responsibilities often cause delays, extra fees, and confusion at ports. To avoid this, always define Incoterms clearly in your purchase order and confirm who handles each part of the shipping process.

3. Skipping Sample Testing and Quality Checks

Some buyers skip sample testing to save time or money, but this can lead to major issues later. Without testing, you may receive bags with poor stitching, wrong sizes, or bad printing. Always request at least two samples, test their load strength, and check printing alignment before approving large production runs.

4. Ignoring Compliance and Labeling Rules

Suppliers are not always aware of rules in your target market, such as REACH in the EU or Prop 65 in the US. Ignoring these can lead to customs problems or fines. To prevent this, share your destination market requirements in advance and ask for compliance certificates or lab test results before production begins.

5. Using the Wrong Customs (HS) Code

Incorrect customs classification can increase import duties or delay clearance. Some suppliers list the product under raw jute instead of finished bags. Always confirm the correct HS code with your customs agent. For most jute bags, it should be 6305.10.00.

6. Assuming Reorders Match Original Quality

Even if your first order goes perfectly, the next one might not. Variations in dye, size, or weave can appear between batches. Ask for photos of new fabric lots, reapprove print files, and request a post-production inspection for large reorders to ensure consistent quality.

7. Relying on Verbal Promises Instead of Contracts

Verbal assurances can lead to disputes about pricing, delivery, or quality. Always use a written purchase order that clearly states specifications, timelines, and penalties for late or poor-quality deliveries. Proper documentation protects both you and your supplier.

Successful bulk purchasing depends on verification, not assumptions. By checking details, testing samples, confirming logistics, and keeping written agreements, you can reduce risks and build long-term partnerships with reliable suppliers.

Conclusion

Buying hessian jute bags in bulk takes more than choosing a product. It requires careful planning, reliable suppliers, and quality checks at every step. When you confirm fabric details, test samples, verify certifications, and clearly define shipping terms, you avoid delays and poor-quality results.

Working with trustworthy manufacturers who follow ethical and environmental standards helps ensure consistency and long-term success. With proper verification and communication, your bulk jute bag orders can be cost-effective, sustainable, and perfectly aligned with your brand goals.